In Part 1 of this series I set the stage by indicating my defining parameters to answer the question, “What arguments would one use to convince an environmentalist to use wood cased pencils?” I’ll say in advance please excuse the length of this post as environmentalus rabidus extremus is a wily and cagy creature and so the foundation and evidence for my arguments must be well constructed.

To accomplish this I will today address a range of environmental impacts with results drawn from an independent third party study performed by Arthur D. Little during 1993. This study was performed on behalf of our former Incense-cedar pencil stock supplier and sister company in our family group, P&M Cedar Products, Inc. P&M operated several sawmills cutting cedar logs harvested in California and Oregon forests into pencil stock and other lumber products and was later integrated back into CalCedar. The pencil stock is converted to pencils slats by our company California Cedar Products Co. for distribution to pencil manufactures. This study, entitled “Pencils: An Environmental Profile”, was designed to develop an improved understanding of the environmental related strengths and vulnerabilities of the Incense-cedar pencil as compared to extruded plastic pencils and to pencils with a recycled paper casing. By recycled paper pencils we mean pencils produced from pencil slats made from compressed recycled paper products, such as the Sanford American EcoWriter pencil produced during the 1990s.

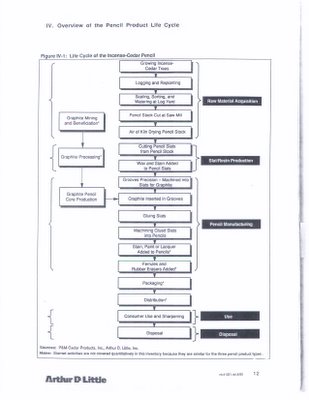

This was a quite extensive study which was complicated by the wide range of manufacturing inputs used in each case. The report references over 75 resource materials used in addition to extensive interviews and on-site investigations and discussions with manufacturers involved in various processes involved through the 5 stage lifecycle. Additional experts in areas of plastics and pulp and paper production were also consulted along with in depth data collection that is all summarized in the report running approximately 100 pages. The environmental analysis focused on evaluating resources consumed and pollutants produced by each of the three pencil casing types during five life cycle stages including:

The environmental analysis focused on evaluating resources consumed and pollutants produced by each of the three pencil casing types during five life cycle stages including:

Raw Material Acquisition – harvesting of timber and production of pencil stock for incense-cedar pencils, oil and natural gas extraction and processing for plastic pencils, and collection and sorting waste paper for recycled paper pencils.

Slat/Resin production – pencil slat production for incense-cedar and recycled pencil production, and plastic resin production for plastic pencils

Pencil Manufacturing – production of pencils from slats for incense-cedar and recycled paper pencils and from plastic resin and wood flour for plastic pencils, including the graphite-plastic extruded core vs. the traditional graphite-clay kiln fired cores used in pencils produced from slats.

Use – consumer use of pencils

Post consumer disposal – disposal of pencil materials, such as pencil shavings and stubs, including landfill and incineration alternatives

The results of the analysis indicated that each of the three pencil products has comparative environmental advantages and disadvantages. On the whole, the incense-cedar wood cased pencil was found to be superior to the other two forms of pencil across a greater number of the dimensions analyzed in terms of reduced impact on the environment. The resource inputs and environmental outputs considered across each life cycle and the key conclusions for each are summarized here:

Environmental Impacts on Resource Inputs

Raw material consumption – Wood pencils require four times more raw materials than the plastic pencil and more than twice the raw materials of the recycled paper material. However a much higher proportion of raw materials used in wood cased pencils are recyclable and the wood pencil consumes less than half the non-renewable resources as either the plastic or recycled paper pencil.

Water consumption – The wood cased pencil consumes approximately 60% of the water used by plastic pencil and approximately 10% of the water consumed by the paper pencil.

Energy consumption – The wood pencil requires approximately ½ the energy required by the paper pencil and a similar quantity of energy as the plastic pencil. The Incense-cedar wood pencil utilizes significantly more renewable energy sources than the plastic or recycled paper pencil.

Environmental outputs

Atmospheric emissions – The wood pencil results in emissions less than or equal to those of the plastic and paper pencil for carbon dioxide, nitrogen oxide, culfer oxide, and particulate matter. The wood pencil emits from 5 to 6 times more carbon monoxide than either the plastic or paper pencil. The wood pencil emits more than three times the organic pollutants emitted by the paper pencil, but only about 10% those of the plastic pencil.

Waste water effluents – The wood pencil emits insignificant quantities of waste water pollutants; emissions of BOD and suspended solids are greater for plastic and paper pencils.

Solid waste – The wood pencil generates less net process solid waste requiring disposal and less post consumer waste than the other two pencil types. While the wood pencil generates more solid waste a greater proportion of this solid waste is later recycled into various products. (See my prior post “Wood Manufacturing Byproducts” for more on CalCedar’s efforts in this area through the years)

Hazardous waste – The wood pencil generates significantly less hazardous waste than either the plastic or recycled paper pencil.

This report is certainly quite helpful to demonstrate the relative environmental superiority of the wood cased pencil versus the two other pencil types. However an objective, intelligent review from the viewpoint of our target consumer environmentalus rabidus extremus would likely yield the following objections:

- The report does not address impacts of graphite production as well as production of other components common to each of the three pencil types. Nor does it address alternative forms of writing instruments.

- The study is now 12 years old and manufacturing processes and relative environmental impacts may have changed due to various improvements in different industries.

- The report focuses on Incense-cedar as a surrogate for all wood casings. Environmental control standards may not be as high or as consistently enforced in other parts of the world where alternative pencil woods now more commonly used in today’s pencils are grown, harvested and processed into lumber, slats and pencils.

- Finally and probably most importantly to rabidus extremus this report does not address wildlife and ecosystem impacts other than the perspective of raw material and water resource consumption in unit volumes.

While in Part 1 I narrowly defined the convincing to be done as limited to selection among cased pencils, some generalizations might be made about comparisons between plastic writing instruments vs. wood cased based on results of this study. These wood favor wood over plastic. Impacts of common cased-pencil components such as graphite, erasers and ferrules were not analyzed in this study since they would have no relative impact in a comparative analysis. How graphite might compare to the vast array of inks used in pens and how ferrules and erasers compare on environmental impacts to other pen or mechanical pencil components is unclear.

As far as time gone by since completion of this study, my only comment is that all things progress in time and improvement could be expected on all fronts maintaining the relative comparative advantages and disadvantages. As to the implication that other wood casings commonly used may be less environmentally sound than Incense-cedar, this is a complicated matter and perhaps a good subject for a future post. In the meantime, all the more reason to purchase genuine Incense-cedar pencils.

On the relative wildlife and ecosystem impacts across the raw material sourcing component it’s correct that this report doesn’t seem to assess this dimension. When it comes to timber harvesting the report does makes note of existing protections under the strong forest practice laws in California and Oregon and indicates the mixed use of selective vs. clear cutting harvest practices according to site specifics. So while I’ve clearly made a cogent argument for the wood cased pencil’s environmental superiority on many dimensions that comunus citizenus may very well accept, it appears I haven’t quite convinced rabidus extremus of this and there is yet work to be done.

As chance would have it I recently received a phone call from a real activist, environmentalist type who had questions about cedar use in pencils. So for Part 3 of this series I’ll go right to the source of our target consumer to get to the bottom of his thinking and make my final effort at conversion of rabidus extremus to Pencil Revolutionary.

Monday, January 16, 2006

Pencils: An Environmental Profile

Or Part 2 in my continuing series on "How to make a Pencil Revolutionary out of an Environmentalist."

Subscribe to:

Post Comments (Atom)

5 comments:

One thing lacking from this post is that many wood cased pencils are manufactured in processes that use much more energy due to shipping materials back and forth. As an example, the tree might grow in California, but it gets cut down shipped to China to have slats made and then shipped to Thailand to get made into pencils and then shipped back to California to be sold as finished product. I doubt the study described takes all that shipping back and forth into account, making wood cased pencils (particularly those from the "California" companies) even worse on the environment. I hate to even bring up the ethical considerations for misleading consumers on product origins using common state names that have little to do with the companies operations.

Anon -

Thanks for your comment.

First, I would need to review details of the study which has been filed away again to see if the transportation impacts you refer to were part of the energy consumption and emmissions data or not. I think they were considered, but cannot recall for sure without checking.

Second, as stated in my post this study was completed in 1993 and represents the most comprehensive data I had available to me to address an inquiry about the relative environmental trade offs of alternative pencil casings and writing instruments. In 1993 our pencil slat manufacturing operations were located in California so at the time of the study the transportation impacts would have been different than today. Indeed a change to overseas manufacturing of the slats and pencils "may" effect the relative environmental impacts, though it's not clear to me off hand that smaller volume shipments of various supply chain components via trucks accross the US are more or less detrimental to the environment than very large consolidated ocean freight shipments. Similar changes in trade flows have occurred for atlernate casing materials as well as other writing instrumants so in order to properly address such an issue would require updating the study. As I noted in the post relative technical developments over time could impact these issues one way or the other.

Next, I used Incense-cedar as a surrogate for wood cased pencils as this is where I had any form of relevant data. Since most pencils consumed here in the US are now produced in China and are made from local Chinese Basswood, rather than cedar this would mitigate on average the transportation impact you mention if there is indeed any significant change.

Finally, if you "hate to bring up ethical considerations" then why do it? I have never intentionally mislead consumers in my Timberlines posts about our company's supply chain and the locations of our manufacturing operations. I am sorry to read you feel otherwise. Our Pencil World eBay store listings note the country of origin of our pencils, so the consumer knows this before purchasing. Incense-cedar grows naturally in California and Oregon and thus stating that our cedar is of California origin is perfectly acceptable and truthful. California Cedar Products Company is a California corporation, headquartered here in this state where we have been located since our founding in 1919. Making the decision to close California based manufacturing operations and relocate offshore was the most difficult business, emotional and ethical decision ever made by our company and a matter of competitive necessity. We have always worked hard to be environmentally responsible in our operations (moving overseas hasn't changed that) and we were the first company in our industry to introduce and promote FSC certified wood for pencils when some customers even implored us not to push this issue. Perhaps our manufacturing is no longer based here which is not uncommon these days. However, the spirit and adventure of the California Republic and the ideals I believe most Californians hold dear are certainly represented within our company's culture and the products and services we bring to market.

Hi

Can you please send me where i can find the study made by "Artur d little"

thanks :-)

The report is private report produced for our former sawmill operations company P&M Cedar Products. The report is in archival files that are stored off site and considerable headache to locate. We do not distribute copies of this report itself and have just published simple synopsis here.

Thanks very much indeed. This has been a very comprehensive look at the problem, given it's pencils we're talking about, and this is the free internet. I'm sure the original report took huge numbers of hours to produce. Someday, there will be a GoogleImpacts site and you'll just enter "pencil" to get a full analysis according to component type. I appreciate your sharing this with us.

Post a Comment